Manufacturing

process

01.

Preparation of technical documentation

Тhe first stage of the production process is the development of technical documentation. The preparation of technical documentation is carried out using the most modern programs for drawings. Once prepared, the technical documentation is approved by the client.

The preliminary preparation of the drawings allows to produce the best details based on the following components:

- Castings configuration

- Gating system

- Pattern-core-mould box equipment

- Optimizing the design and product cost, according to its particular application

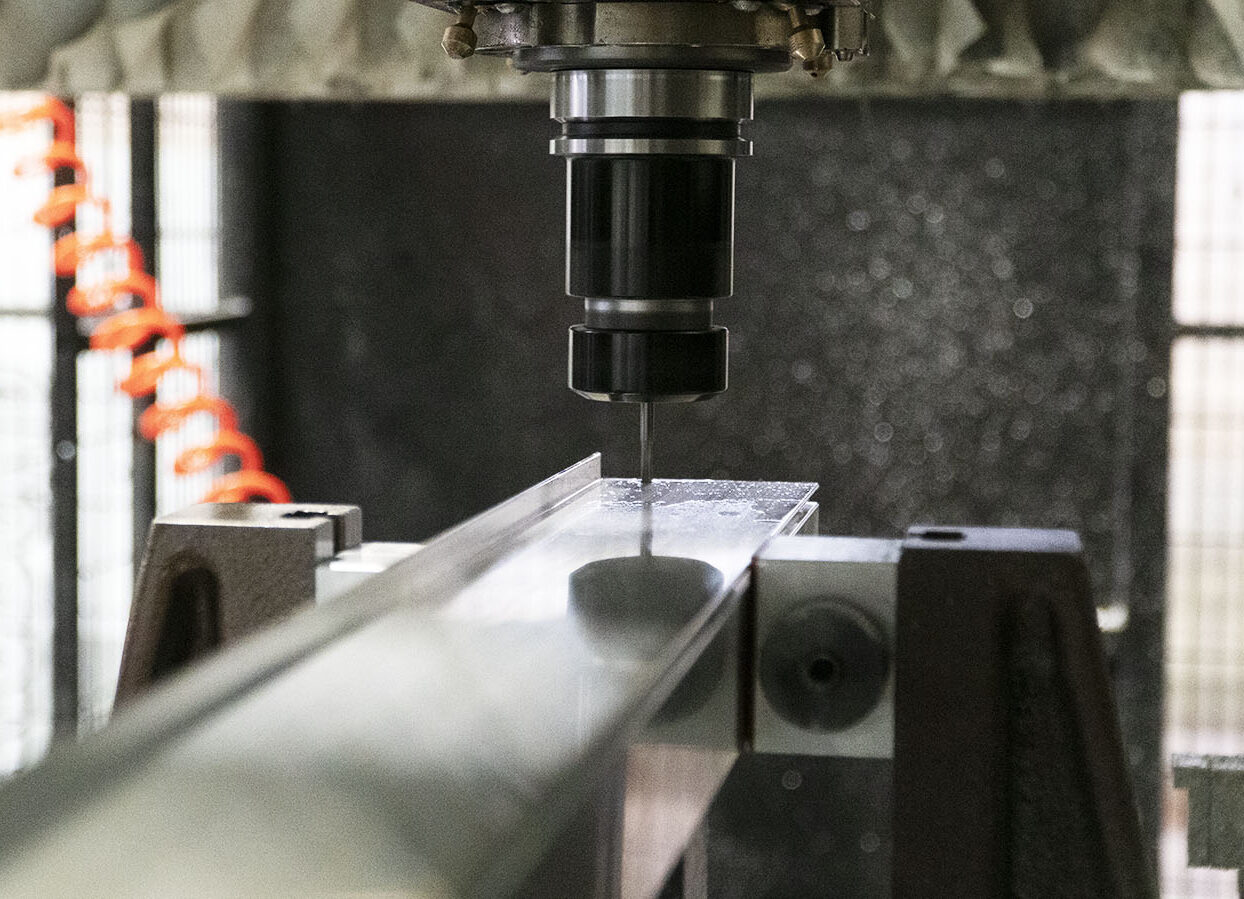

02.

Production of model equipment

The elaborating of new pattern-module box equipment is carried out in a separate workshop, equipped with CNC machines.

Their main purpose is through the processing of various types and shapes of cores, which are intended to give smoothness and accuracy of the casting holes. Cores are made of special mixtures, which are consistent with the size and complexity of each individual part.

We have a diverse cash park and a nomenclature of sets of model equipment, including over 2000 names and sizes (models, heart boxes, blanket equipment).

About 150-200 new parts are developed and assumed annually.

03.

Moulding & Casting

The molding is carried out in shell forms and sand bentonite mixtures.

/Възможностите на предприятието позволяват производството на 240 т. отливки годишно, с единична маса от 0,3 кг. до 200 кг. и размери до 1000 х 1500 мм.

Depending on the castings dimensions the moulding is machined or made by hand. The moulding process is accompanied by the preparation of special moulding and core mixes.

Разтопяването на метала се осъществява в 2 бр. 160 – килограмови индукционни пещи за стомани и чугуни. Работата с този вид пещи дава възможност за непрекъснат контрол върху химическия състав на отливания метал и качеството на произведената продукция, което допълнително подобрява прецизността на работата./

04.

Qualification of castings

The qualification of the castings is made after cleaning and cutting the casting system.

05.

Heat treatment

For the heat treatment we have two electric resistance furnaces PEK -20 and PEK – 45.

Heat treatment is a process of thermal effect on the metals or metal alloys, with the purpose of altering their structure and physical properties. It usually involves heating or cooling and holding at a certain temperature.

We perform classical thermal processes - annealing, normalization, quenching, tempering and aging, which is determined by the specific metal grade that is produced.

06.

Мechanical processing

After the thermal process castings undergo finishing work - cleaning, shot blasting, painting.

Мachining is performed depending on the requirements and serial number of parts of universal metalworking machines and CNC machines.